-

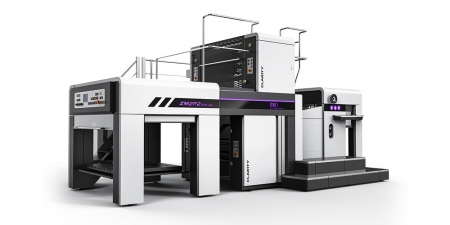

ZM2P2104-AL Double-Sided Two-Color Offset Printing Machine

Read MoreMachine features:◆High speed and high efficiency (technology and guarantee)

13000 sheets/hour high speed and large format: All printing cylinders adopt double-row precision tapered roller bearings and 5-level precision gears to ensure running accuracy.

Adopt quick plate loading and positioning mechanism, electric control precise plate drawing device, making plate loading and changing faster and easier.

◆Fine prints

It adopts soft and hard structure, good dot reducibility, and excellent printing quality.

Accurate overprinting: double-sided alternate printing is used to ensure accurate overprinting on both sides. The printing plate cylinder can be adjusted in the axial and radial directions without stopping, and the mechanism adopts the latest patented technology.

◆Advanced structure

Easy to operate: The man-machine interface controlled by the touch screen centrally controlled by PLC program makes the equipment highly automated and easy to operate. It adopts pneumatic control roller clutch, ink-wash clutch, and has automatic clutch program and independent step-by-step operation options.

◆Strong applicability

Strong thin paper printing capacity: unique and stable high-speed paper feeder, conjugate cam paper feeding mechanism and downward swing front gauge, so that thin paper printing can reach a higher speed. External adjustment mechanism of paper thickness press.

◆Safe and reliable

The whole machine is designed according to the structure of heavy-duty high-speed operation, with a total weight of about 27 tons, which is stable and durable. The printing plate, rubber, and impression cylinder are sprayed with stainless steel, which is corrosion resistant.

-

ZM2P104-AL Double-Sided Monochrome Offset Printing Machine

Read MoreMachine features:◆High speed and high efficiency (technology and guarantee)

13000 sheets/hour high speed and large format: All printing cylinders adopt double-row precision tapered roller bearings and 5-level precision gears to ensure running accuracy.

Reduce equipment downtime and adjustment time: adopt quick plate loading and positioning mechanism, electric control precision plate drawing device, so that plate loading and plate changing are faster and easier.

◆Fine prints

It adopts soft and hard structure, good dot reducibility, and excellent printing quality.

Accurate overprinting: double-sided alternate printing is used to ensure accurate overprinting on both sides. The printing plate cylinder can be adjusted in the axial and radial directions without stopping, and the mechanism adopts the latest patented technology.

◆Advanced structure

Easy to operate: The man-machine interface controlled by the touch screen is centralized, and the equipment is controlled by the PLC program to have a high degree of automation and easy operation. It adopts pneumatic control roller clutch, ink-wash clutch, automatic clutch program and independent distribution operation options.

◆Strong applicability

Strong thin paper printing capacity: unique and stable high-speed paper feeder, conjugate cam paper feeding mechanism and lower swing front gauges, so that thin paper printing can also reach a higher speed. External adjustment mechanism of paper thickness press.

◆Safe and reliable

The whole machine is designed according to the structure of heavy-duty high-speed operation, with a total weight of about 17 tons, which is stable and durable. The printing plate, rubber, and impression cylinder are sprayed with stainless steel, which is corrosion resistant.

-

AKIYAMA JP40 Double-Sided Multi-Color Sheet-Fed Offset Printing Machine

Read MoreMachine features:From the high-speed feeder of 15000SPH, to the preset remote control system such as paper size preset, as well as the automatic equipment such as semi-automatic plate loading system and automatic blanket cleaning system, it not only guarantees the high-speed stability of the equipment, but also enables the equipment to adapt to the long Edition and short edition printing business.

◆Paper size preset

◆Printing pressure preset

◆Registration remote adjustment (circumferential, axial, diagonal)

◆Semi-automatic plate loading system

◆Blanket automatic cleaning system (also used to clean the impression cylinder)

◆Preset ink volume (optional for JP1P140)