-

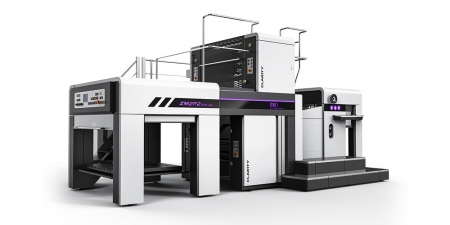

ZM2P2104-AL Double-Sided Two-Color Offset Printing Machine

Read MoreMachine features:◆High speed and high efficiency (technology and guarantee)

13000 sheets/hour high speed and large format: All printing cylinders adopt double-row precision tapered roller bearings and 5-level precision gears to ensure running accuracy.

Adopt quick plate loading and positioning mechanism, electric control precise plate drawing device, making plate loading and changing faster and easier.

◆Fine prints

It adopts soft and hard structure, good dot reducibility, and excellent printing quality.

Accurate overprinting: double-sided alternate printing is used to ensure accurate overprinting on both sides. The printing plate cylinder can be adjusted in the axial and radial directions without stopping, and the mechanism adopts the latest patented technology.

◆Advanced structure

Easy to operate: The man-machine interface controlled by the touch screen centrally controlled by PLC program makes the equipment highly automated and easy to operate. It adopts pneumatic control roller clutch, ink-wash clutch, and has automatic clutch program and independent step-by-step operation options.

◆Strong applicability

Strong thin paper printing capacity: unique and stable high-speed paper feeder, conjugate cam paper feeding mechanism and downward swing front gauge, so that thin paper printing can reach a higher speed. External adjustment mechanism of paper thickness press.

◆Safe and reliable

The whole machine is designed according to the structure of heavy-duty high-speed operation, with a total weight of about 27 tons, which is stable and durable. The printing plate, rubber, and impression cylinder are sprayed with stainless steel, which is corrosion resistant.

-

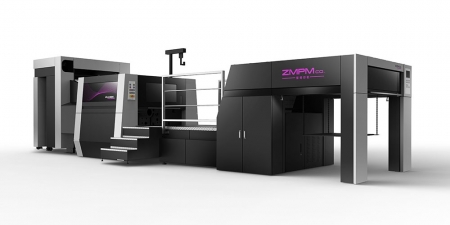

ZM2P104-AL Double-Sided Monochrome Offset Printing Machine

Read MoreMachine features:◆High speed and high efficiency (technology and guarantee)

13000 sheets/hour high speed and large format: All printing cylinders adopt double-row precision tapered roller bearings and 5-level precision gears to ensure running accuracy.

Reduce equipment downtime and adjustment time: adopt quick plate loading and positioning mechanism, electric control precision plate drawing device, so that plate loading and plate changing are faster and easier.

◆Fine prints

It adopts soft and hard structure, good dot reducibility, and excellent printing quality.

Accurate overprinting: double-sided alternate printing is used to ensure accurate overprinting on both sides. The printing plate cylinder can be adjusted in the axial and radial directions without stopping, and the mechanism adopts the latest patented technology.

◆Advanced structure

Easy to operate: The man-machine interface controlled by the touch screen is centralized, and the equipment is controlled by the PLC program to have a high degree of automation and easy operation. It adopts pneumatic control roller clutch, ink-wash clutch, automatic clutch program and independent distribution operation options.

◆Strong applicability

Strong thin paper printing capacity: unique and stable high-speed paper feeder, conjugate cam paper feeding mechanism and lower swing front gauges, so that thin paper printing can also reach a higher speed. External adjustment mechanism of paper thickness press.

◆Safe and reliable

The whole machine is designed according to the structure of heavy-duty high-speed operation, with a total weight of about 17 tons, which is stable and durable. The printing plate, rubber, and impression cylinder are sprayed with stainless steel, which is corrosion resistant.

-

ZMA92C Multifunctional Gravure Printing Machine

Read MoreMachine features:◆High paper pile feeder, the height of paper pile can reach 1500mm, paper can be fed and collected without stopping the machine.

◆The cylinder clutch and the squeegee clutch are both pneumatically controlled, with simple structure and smooth action.

◆This machine adopts dual drying system of hot air knife and far infrared rays, which is suitable for high-speed printing.

◆This machine has a variety of optional functions, which can achieve special printing effects such as UV matte, ice, and wrinkling.

◆Swing paper delivery mechanism controlled by new conjugate cam.

◆Efficient and stable delivery device.

◆No impact roller bite opening and closing system.

-

ZMA105 Multifunctional Gravure Printing Machine

Read MoreMachine features:This machine has advanced structure, complete functions, simple operation and stable operation.

◆Adopting Japanese high-speed offset press front rules and paper delivery design technology, the printing speed can reach 13,000 sheets per hour, the paper delivery is stable, the positioning is accurate, and the noise is low;

◆The detonation and wrinkle lamp holder adopts an integral movable structure, and the position of the detonation and wrinkle lamp can be adjusted by manual operation outside the machine to produce different printing effects, which is more in line with the requirements of printing individuality;

◆UV curing, infrared drying and detonating lamps are all supported by a water-cooled chassis to reduce internal heat accumulation and effectively prevent printed products from scalding.

◆Empty sheet, crooked sheet, double sheet photoelectric detection and mechanical double sheet detection, automatic shutdown of paper feeding failure;

◆Double-diameter embossing and rolling, small paper deformation, high printing speed, plug-in blanket, easy to replace;

◆Pneumatic control of roller clutch and squeegee clutch, automatic adjustment of paper thickness without stopping the machine, simple structure and convenient maintenance;

◆The non-marking paper delivery tooth row avoids the shadow of ultraviolet light and improves the curing effect.